The Volkswagen Commercial Vehicles Group

THE CUSTOMER IS AT THE HEART OF ALL ACTIVITIES

Volkswagen reorganized its commercial vehicles business in 2015. The Volkswagen Commercial Vehicles group comprises the business with light as well as mid-sized and heavy commercial vehicles. The activities of MAN Truck & Bus, MAN Latin America – whose unit sales are essentially the responsibility of Volkswagen Caminhões e Ônibus – and Scania have been combined in Volkswagen Truck & Bus GmbH so as to cater to the specific interests and needs of commercial vehicle customers in the best possible manner.

The business with trucks, buses, and transporters differs fundamentally from the passenger car business. Commercial vehicles are capital goods: they are purchased in order to earn money with them. Customers are consequently very cost-conscious. A truck covers around two million kilometers in the course of its useful life. Therefore, it is not just the purchase cost that plays a key role in the decision to buy. The lower a vehicle’s fuel consumption and the more efficiently the service, maintenance and repairs are carried out, the greater the customer’s profit margin. For this reason, the total operating costs, i.e. the costs during the vehicle’s entire useful life, are the key metric for the investment decision.

Other key factors for the customer include the reliability and availability of a commercial vehicle: a truck or bus only earns money when it is on the road. Volkswagen’s commercial vehicles brands offer services especially geared to customer requirements in order to optimize the vehicles’ operating times. Examples of the strong focus on customers, who are businesses just like ourselves, include the lease of trucks and trailers, the provision of replacement vehicles, services geared to working times, service contracts specifically tailored to customer needs, and telematic services, but also training the drivers.

The global truck and bus markets are shaped by different customer needs. For this reason, there is no one “standard vehicle” for worldwide use. Trucks and buses need to be individually adapted to different customer specifications and regional conditions. For example, freight forwarders in India have different robustness and cross-country-mobility requirements for the vehicle than those operating their vehicle fleets in Europe. The challenge is nevertheless to design as many of the vehicle’s components as possible for use worldwide through smart design.

Tractor for semitrailer, gravel tipper, fire truck, furniture van, gritting vehicle, cement truck, delivery van, refrigerated truck, or tradesman’s van – the range of possible uses of commercial vehicles and thus their possible configurations are almost unlimited and many times greater than for passenger cars; however, the production volume is significantly lower. Close cooperation with the bodybuilders is therefore highly important when we need to realize the optimum vehicle solution for our customers.

The business with city buses, intercity buses, coaches and small buses is also highly complex. Modern city bus concepts – for example based on a hybrid or electric drive – will play a part today and in the future in saving the world’s ever increasing high-density urban areas from gridlock. Long-distance buses are already used in many regions of the world as a very environmentally friendly means of transport that is inexpensive for passengers. This market is also gaining significance in Europe.

The market for capital goods, which commercial vehicles are part of, is very cyclical. In an economic upturn, the need for transport and thus the demand rises sharply, whereas in economically difficult times demand falls just as sharply. The production fluctuations arising as a result require a high degree of flexibility from manufacturers.

Global demand for commercial vehicles is expected to rise in the next few years. At the same time, the requirements placed on commercial vehicle manufacturers keep increasing. Emissions laws, safety regulations, and tax and toll models require a high degree of innovation and lead to technically highly developed and complex products. Furthermore, commercial vehicle manufacturers are increasingly evolving from pure vehicle suppliers into providers of tailored logistics services.

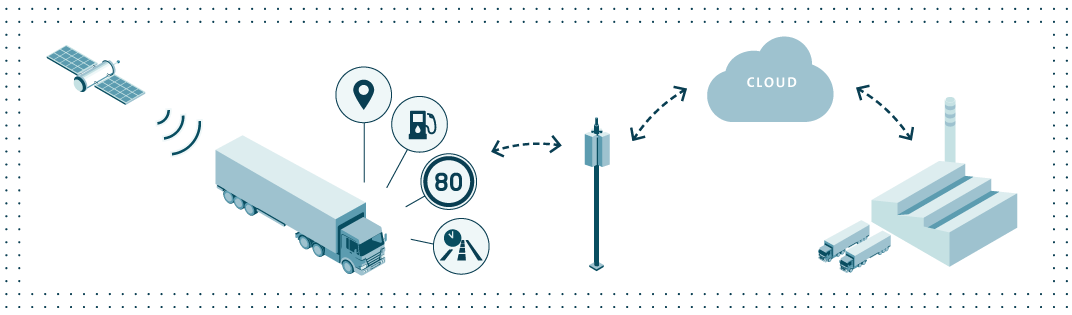

The key performance parameters for manufacturers are the enhancement of alternative drive systems and fuels and customer-centric connectivity features. For example, Scania has already handed more than 160,000 networked trucks over to customers. Subject to the operator’s consent, the vehicles transmit information about their position and their operating status such as fuel consumption and driving behavior at short intervals. This information provides additional efficiency and safety for our customers and enables the manufacturers to expand their business model and thus achieve greater independence from economic cycles. We will tackle these challenges with individual solutions based on common platforms.

Increasingly strict emissions regulations, the customer’s desire to save fuel and the interest in alternative drive systems are becoming an increasing focus. For example, natural gas is used as an economical and clean drive system for city buses from MAN and Scania. To be able to use natural gas engines for long-distance trucks and buses, however, LNG (liquefied natural gas) is required instead of CNG (compressed natural gas) because this is the only way to achieve the necessary energy density and thus the desired range. Better infrastructure is needed for natural gas to be widely used as a fuel. For instance, fuel station networks have only been sufficiently developed in a few countries. Hybrid vehicles offer savings of up to 20% of the fuel in distribution transport. Considerable potential is also becoming apparent in long-distance transport, where savings of up to 8% are possible.

A fully electric drivetrain is currently not practical due to the still high weight of the battery and the associated decrease in the payload in long-distance transport; in distribution transport we are currently testing the e-Caddy in the light commercial vehicles segment – the e-load up! is already available. Trials are also being run for mid-sized trucks. Hybrid solutions make sense in city buses due to the stop-and-go traffic. MAN, for example, introduced the full hybrid bus Lion’s City Hybrid back in 2010. Both MAN and Scania are currently developing zero-emissions fully electric city buses.

The Volkswagen Group’s commercial vehicles brands are not only working on increasing efficiency and environmental compatibility, but are also intensively developing new driver assistance systems to improve safety. Existing systems such as the emergency braking system and the lane assist system are being continuously improved. Further opportunities for safe driving arise from connectivity, for example in the field of car-to-car communication.

DIGITALIZATION IN THE COMMERCIAL VEHICLES BUSINESS

Cross-brand management of the commercial vehicles business field is part of the organizational structure at Volkswagen Truck & Bus GmbH. A matrix structure guarantees that our strong brands continue to be able to act independently and optimally serve their respective customer groups. At the same time, it ensures that economies of scale and synergies are achieved through cooperation in purchasing, production and development.

The strategic objective is clear: Volkswagen Truck & Bus is aiming to become a Global Champion. For us, however, it is not the sales volume that has priority, but profitability, practical innovations and the expansion of our global presence. The customer is always at the heart of all activities.

In order to achieve these objectives, the brands will work together on new business models and massively advance digitalization in the commercial vehicles business. In addition, a platform strategy is planned for mid-sized and heavy commercial vehicles in the future. Common platforms for gearboxes, axles, selected cab components and driver assistance systems for trucks and buses are currently in development. In the long-term, the focus is on the overall powertrain as a truck’s most important cost driver. In view of the long product lifecycles, it will be ten to fifteen years before the potential arising from this is fully exploited. The common components will be the platform for creating brand-specific solutions, although the brands will remain easy to differentiate for the customer. By combining activities within Volkswagen Truck & Bus, we estimate long-term additional synergy potential of at least €650 million on average.

There will also be synergies within light commercial vehicles. From a technical perspective, these vehicles are more closely related to the passenger car and bring developments in connectivity and driver assistance systems to our customers who use their vehicle commercially.